In a production line, all decisions influence the quality, cost, and delivery times. When your components are small, complex, or mission-sensitive, the welding process you select may mean the difference between meeting your goals and suffering delays, rejection, and compliance nightmares.

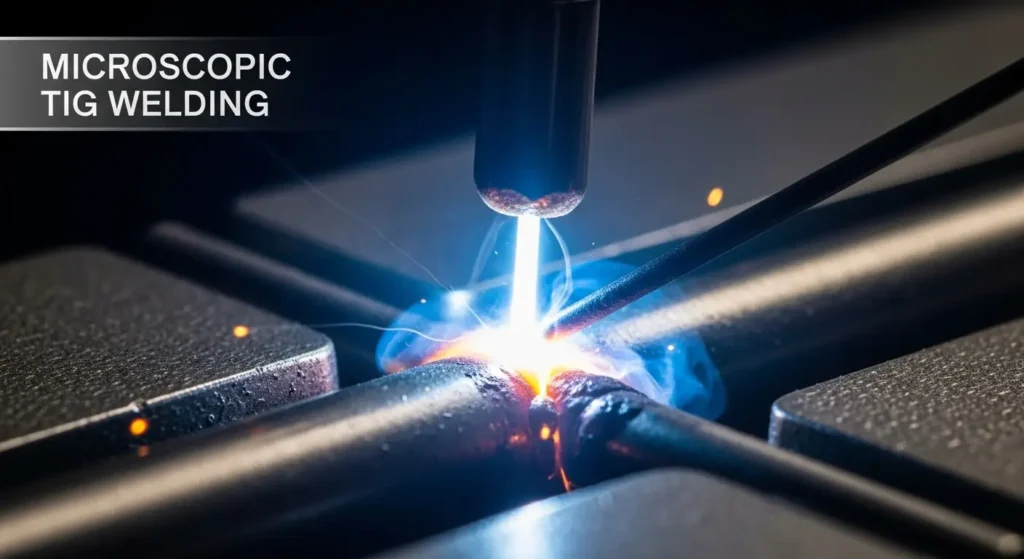

Microscopic TIG welding is a demonstrated manufacturing investment that pays back in many ways that we will discuss below.

Reliability you can count on in every production run

Almost identical is never good enough in production welding. Each of the parts you send out of your facility should be of the same quality, regardless of whether it is the first or the ten-thousandth one.

Microscopic TIG welding is conducted in such a way that very precise heat and filler are applied under magnification. This leads to consistent weld profiles. The accuracy of the process guarantees:

- Precise penetration depth to ensure repeatable joint strength.

- Narrow conforming bead profiles as per specification.

- No batch-to-batch difference in mechanical performance.

Such consistency eradicates the costly turnaround of rework requests, inspection failures, and discarded raw materials associated with less accurate methods.

Minimizes the Heat-Affected Zone to safeguard sensitive components

The heat-affected zone (HAZ) may be your worst enemy when working with small or delicate parts in welding. Too much heat will lead to distortion, weaker materials, and, in the case of electronics, even the failure of adjoining parts.

In microscopic TIG welding, the heat is focused where needed and not in any other place. This is essential for:

- Thin-walled tubing in medical devices.

- Miniature electronic enclosures that can not endure warping.

- Mixed-metal joints in which the alloy on one side of the joint is more sensitive to heat.

Minimizing the HAZ during this process leaves you with the original properties of the base material. It also limits downstream failures during assembly and final use.

Minimizes post-weld processing time

Every minute you have to spend grinding, polishing, or cleaning a weld retroactively costs the production line. In high-volume production, those few minutes can add up to hours, days, or weeks of lost throughput.

Microscopic TIG welding creates smooth and clean joints, which in most instances need minimal or no finishing at all. This implies that you are in a position to transport components right after welding to the next stage of production. In thousands of units, this amounts to:

- Less labor expenses

- Faster cycle times

- Quicker order fulfillment.

Less scrap and rework

Scrap is one of the silent killers of profit in manufacturing. Reject rates as low as 2-3% of a high-volume order can total thousands of dollars of lost material and labor.

The accuracy of microscopic TIG welding will also decrease the chances of poor welds. Operators can visualize exactly where they are working, manage filler addition down to the micron, and manage heat input in real time. This leads to:

- Reduced defects.

- Reduced wastage of materials.

- Fewer rework hours.

- More consistent output plans.

In industries where materials such as titanium or specialty alloys have a high price tag, big reductions in scrap volumes result in huge profits.

Flexibility in material and application

Production can frequently involve working with a blend of materials; a week of stainless steel, the next week titanium, and possibly varying metal joints in between.

Micro TIG welding is very flexible. It can:

- Process biocompatible metals for medical applications without changing their properties.

- Join unlike metals without undue damage to either side.

- Process reflective or high-conductivity materials, such as copper, which other processes find difficult to process.

The flexibility here implies that you can minimize hand-offs, supply chain complexity, and the chances of delay.

Conformance with no stress

Perhaps you work in regulated sectors, like medical devices, electronics, or aerospace. In that case, you already know requirements like ISO 13485, FDA QSR, or IPC-A-610.

These high standards are easier to achieve with microscopic TIG welding due to the repeatability and control. The right supplier, like Micro Weld, gives you:

- Traceability with full process documentation.

- Regulatory-compliant inspection reports.

- Weld data that is compatible with your quality management system.

This way, compliance becomes a regular procedure.

Explore our consulting category to get your hands on interesting topics.

Quicker throughput without quality tradeoff

The speed of production is important, but not at the cost of quality. The microscopic TIG welding strikes the balance by making the welds correct the first time.

With a low defect rate and minimal post-processing, you can maintain a smooth production flow. That means:

- Delivering within short deadlines, without compromising on quality.

- Optimizing machine and operator availability.

- Creating space to handle more projects.

The overall impacts on delivery reliability can enhance customer retention and create avenues for more extensive contracts.

Summing up

Microscopic TIG welding is more expensive per unit than certain bulk welding processes. However, in production, a unit output cost does not always equate with the cost of the project as a whole.

When you account for:

- Rework and scrap savings.

- Less labor due to minimal finishing work.

- Prevented losses due to failure in the field or warranty claims.

- Increase in throughput and on-schedule deliveries.

…microscopic TIG welding will be the more lucrative option for production welding.